Breakthrough of LONGi Green Energy: LONGi Green Energy Technology Co., Ltd., as the first affiliated unit, published a research paper online in the journal "Nature", reporting the research achievement that the photoelectric conversion efficiency of crystalline silicon batteries has broken through 27% through the all-laser patterning process. The team has developed a new type of dense heterojunction passivation contact, breaking through the long-standing bottleneck of heterojunction preparation in the industry within the temperature range of 180 - 210°C. The process temperature has reached 240°C. Meanwhile, the all-laser patterning process and the low-indium and silver-free metallization scheme have been developed, laying the foundation for the production of low-cost and high-efficiency BC batteries and pointing out the direction for the development of crystalline silicon solar cell technology.

For a long time, improving the conversion efficiency of crystalline silicon solar cells has been an unremitting goal pursued by researchers and the industry. The level of conversion efficiency directly determines the ability of solar cells to convert light energy into electrical energy, which in turn affects the cost and application scope of photovoltaic power generation. Early crystalline silicon solar cells had relatively low conversion efficiency due to limitations in material quality, manufacturing processes, and other factors, which to a certain extent restricted the competitiveness of solar energy in the energy market. However, with the continuous evolution of technology, significant breakthroughs in the efficiency of crystalline silicon solar cells have been achieved in recent years.

Material innovation is one of the key factors driving efficiency improvement. For instance, the research, development, and application of new silicon materials have significantly reduced impurities and defects inside the materials, minimizing electron loss during transmission and thereby enhancing photoelectric conversion efficiency. Meanwhile, progress has also been made in optimizing the thickness of silicon wafers. On the premise of ensuring sufficient light absorption, the use of thinner silicon wafers not only reduces material costs but also helps improve the overall performance of solar cells. Taking an ultra-thin silicon wafer developed by a certain enterprise as an example, when applied in solar cells, it effectively increases the short-circuit current density, laying a solid foundation for efficiency breakthroughs.

Structural optimization also plays an indispensable role. The emergence of Back Contact (BC) cell technology has become a major highlight in efficiency improvement. This type of cell places both positive and negative electrodes on the backside, leaving no grid lines to block the front surface. This design increases the area of the cell available for sunlight absorption and optimizes its optical performance. In terms of electrical performance, the passivated contact technology of BC cells has reached a high level, enabling separate optimization of the front and back efficiency of the cell. This avoids the issue in traditional structures where the front performance is restricted by the back design. Theoretically, the maximum efficiency limit of crystalline silicon cell technology is 29.56%, and BC technology has become a powerful approach to approach this value. Currently, the efficiency of some BC technology-based cells has achieved significant improvements, outperforming other mainstream technologies.

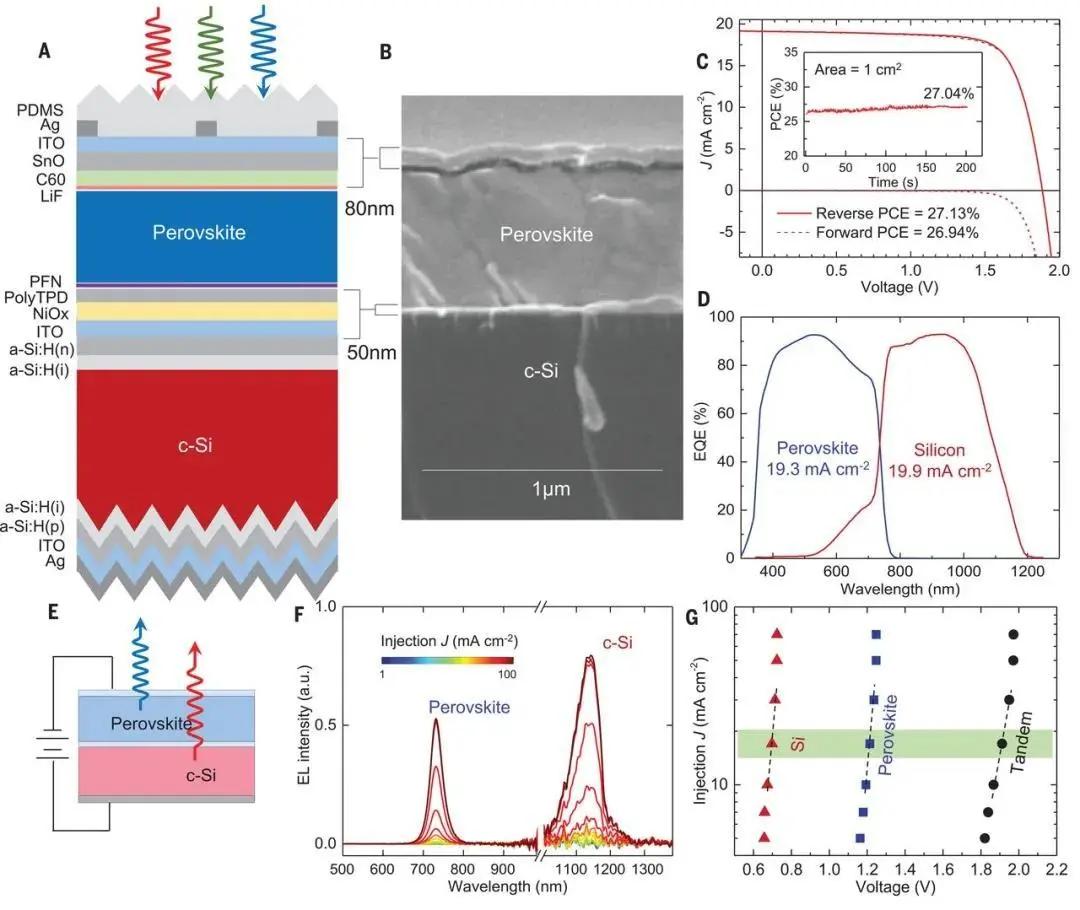

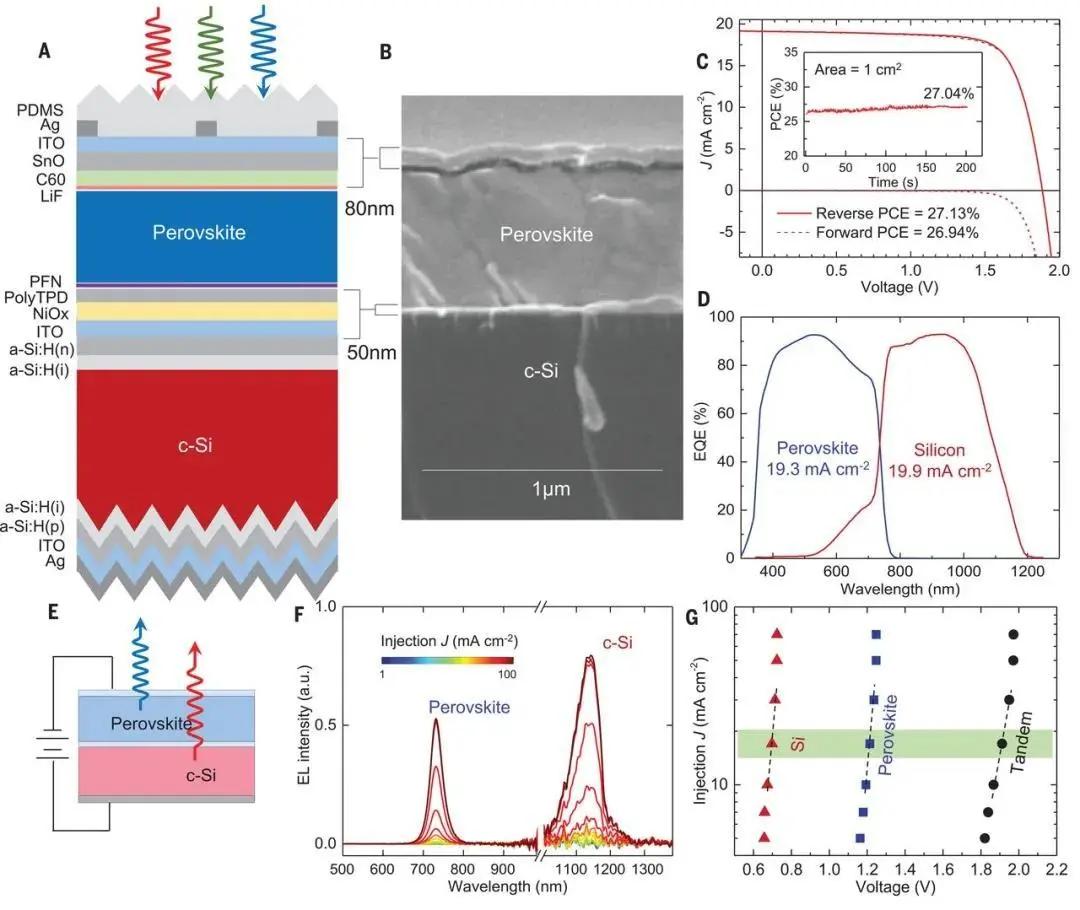

Numerous enterprises have played a crucial role in promoting efficiency breakthroughs of crystalline silicon solar cells. As a leader in the industry, Longi Green Energy has achieved remarkable results. In April 2025, the photoelectric conversion efficiency of its independently developed Hybrid Back Contact (HIBC) crystalline silicon solar cell reached 27.81%, pushing the exploration of the limits of monocrystalline silicon photovoltaic cells to a new height. In June of the same year, Longi Green Energy announced that the conversion efficiency of its independently developed large-area (260.9cm²) crystalline silicon-perovskite two-terminal tandem solar cell had reached 33%, while the efficiency of BC cell modules exceeded 26%. These achievements not only demonstrate the company's technological strength but also point out the direction for the development of the entire industry. Through material innovation and structural optimization, while improving efficiency, new paths have been opened up for further reducing the cost of photovoltaic power generation.

The breakthrough in the efficiency of crystalline silicon solar cells has had a profound impact on the photovoltaic industry and even the global energy pattern. On one hand, higher conversion efficiency means that more electrical energy can be generated under the same lighting conditions. This will effectively reduce the levelized cost of electricity (LCOE) of photovoltaic power generation, enhance the competitiveness of solar energy in the energy market, and accelerate the transformation of solar power generation from a supplementary energy source to a primary energy source. On the other hand, efficiency breakthroughs will also promote collaborative innovation in the upstream and downstream of the photovoltaic industry, drive the upgrading and development of related industrial chains, and create more economic and social benefits.

Looking ahead, with the continuous increase in scientific research investment and the advancement of technological innovation, the efficiency of crystalline silicon solar cells is expected to further improve and continuously approach the theoretical limit. This will provide a solid guarantee for the realization of global sustainable energy development, enabling solar energy, as a green energy source, to play a more important role in addressing climate change and meeting energy demand, thus opening a new era of cleaner and more efficient energy.